5S and 6S Safety Signs and Tags by Caledonia Signs - Trade Only Supplier

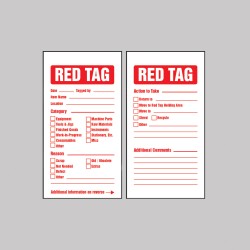

A 5S/6S tagging system is an effective tool for identifying, evaluating, and managing unnecessary or misplaced items in the workplace. Tags, often colour-coded, are used during the "Sort" phase of the 5S process to flag items that are no longer needed, are in the wrong location, or require further assessment. This simple, visual system helps teams make objective decisions about what to keep, move, or remove, thereby reducing clutter and improving overall organisation. It creates a structured and transparent way to declutter work areas, making them more efficient and safer.

Using a tagging system also encourages employee involvement and accountability. When staff members are responsible for tagging and reviewing items in their workspaces, they become more invested in maintaining order and contributing to continuous improvement. It fosters teamwork and communication, as employees must often collaborate to decide what actions to take with tagged items. This engagement not only improves the effectiveness of the 5S/6S process but also boosts morale by involving everyone in decisions that affect their daily work.

Additionally, the tagging system serves as a record of action and progress. Each tag often includes information such as the date of tagging, the reason for tagging, and the person responsible. This creates a paper trail that can be reviewed during audits or team meetings to ensure timely follow-up and accountability. Managers and safety officers can use this documentation to track how effectively the 5S/6S program is being implemented, helping to identify patterns or recurring issues that need attention.

Finally, a 5S/6S tagging system supports the sustainability and safety components of the methodology. Items that pose potential safety hazards can be quickly identified and removed or relocated, directly contributing to a safer work environment, the focus of the sixth -S- in 6S. The continued use of tagging promotes a cycle of regular review and improvement, preventing workspaces from falling back into disarray. As a result, the workplace becomes more organised, productive, and secure, reinforcing a culture of discipline and continuous improvement.

Red Tag - Quality Control - Double Sided Tag - Includes Cable Ties (Pack of 10) Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs...

5S - 6S Information - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. ..

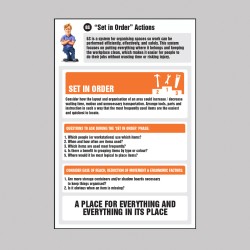

Set in Order Actions Information - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

Sort Actions Information - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. ..

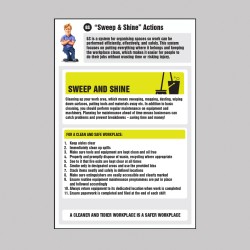

Sweep & Shine Actions Information - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

Keep All Areas Clean and Tidy - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

A Place for Everything - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. ..

Maintain your Workstation - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

Red tag Holding Area - Poster Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

Red Tag Holding Area Items for Disposal Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

Keep All Areas Clean and Tidy Safety Signs

Remind employees, contractors, and visitors to maintain cleanliness and organization in a workspace. Clean and orderly areas reduce hazards, prevent slips, trips, and falls, improve operational efficiency, and create a safer and more pleasant working environment. The sign reinforces good housekeeping practices and encourages personal responsibility for shared spaces. This sign should be placed in..

A Place for everything and everything in Its Place Safety Signs

Promote organization, efficiency, and safety in the workplace. It encourages employees and visitors to return tools, equipment, and materials to their designated locations after use. This reduces clutter, prevents loss or damage, minimizes hazards such as trips or falls, and improves workflow by making items easy to locate when needed. This sign should be placed in workshops, factories, warehouse..

Maintain your Workstation in a Tidy Condition Safety Signs

Remind employees to keep their individual work areas clean, organized, and free of unnecessary clutter. A tidy workstation reduces the risk of accidents such as slips, trips, or falls, prevents damage to equipment or materials, and promotes a more efficient and productive work environment. It also helps maintain hygiene and ensures that tools, documents, and resources are easily accessible when ne..

Red Tag Holding Area Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. Hel..

Good House Keeping Makes our Work safer Safety Signs

Remind employees and visitors that maintaining clean, organized, and orderly work areas is essential for safety. Good housekeeping reduces hazards such as slips, trips, and falls, prevents accidents with machinery or equipment, and minimizes the risk of fire or contamination. It also promotes efficiency by making tools, materials, and workspaces easier to access and navigate. This sign should be p..

Supplies Stored Here Safety Signs

Advise staff and visitors of 5s and 6S (steps to safety) procedures and locations throughout your warehouse and factory units. A neat and tidy workplace will see higher productivity; produce fewer errors; improve deadlines; promote communication; reduce waste and lower costs. Materials Explained Below is a more detailed description of the materials this particular safety sign is available in. ..